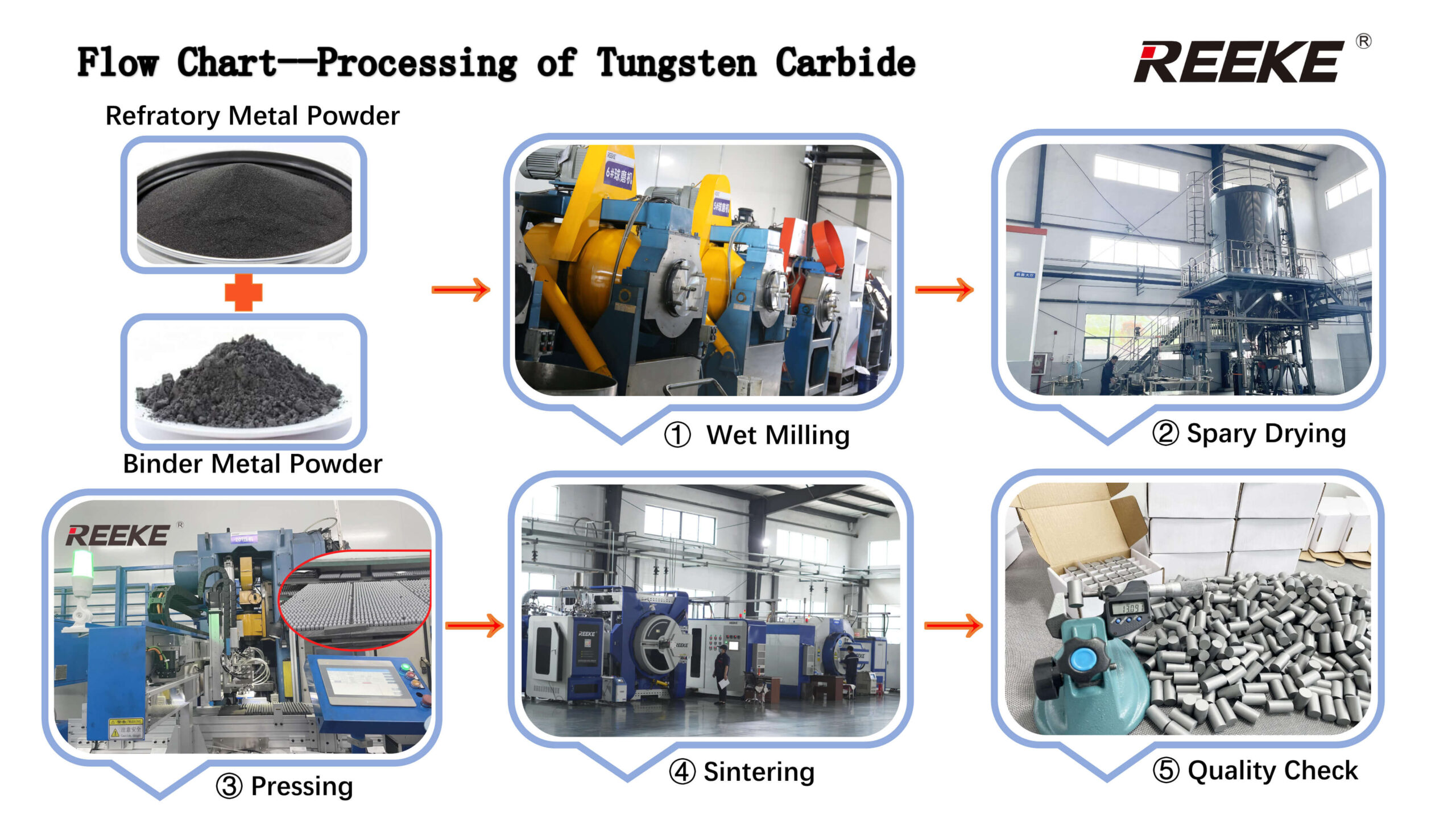

Tungsten carbide is a grey-black powder that can be pressed and made into shapes through sintering. It is two times as stiff as steel, and has double the density of steel. It is commonly used in drilling, sports equipment and jewelry.

The density of WC powder is 15.63 g/cm³, which is as solid as a rock, giving people heavy strength; the elastic modulus is as high as 710GPa, as flexible as a spring, with both a strong side and a flexible side; compressive strength At 56MP, this powerful endurance is as firm and stable as a mountain; the thermal expansion coefficient is 6.9×10^-6/K, and small changes are particularly obvious on it. This stable physical property makes it It can maintain its original characteristics under various environmental conditions; it has good electrical and thermal conductivity properties, and is like a carrier of flowing current and heat, transmitting energy and information.

Thanks to their excellent hardness, carbide powders are used for heavy industrial use such as hard metal-cutting tools, wear parts, mining and road construction tools. For instance, titanium carbide and tungsten carbide are used to coat metals in cutting tools.In addition, WC powder can also be used in the manufacture of wear-resistant materials, aerospace cables and other fields. In terms of wear-resistant materials, tungsten carbide powder can be mixed with metal binders to form a wear-resistant coating, which has excellent wear resistance and corrosion resistance and is suitable for various wear-resistant occasions. In terms of aerospace cables, tungsten carbide powder can be used as an additive for cables to improve the wear resistance and corrosion resistance of the cable.