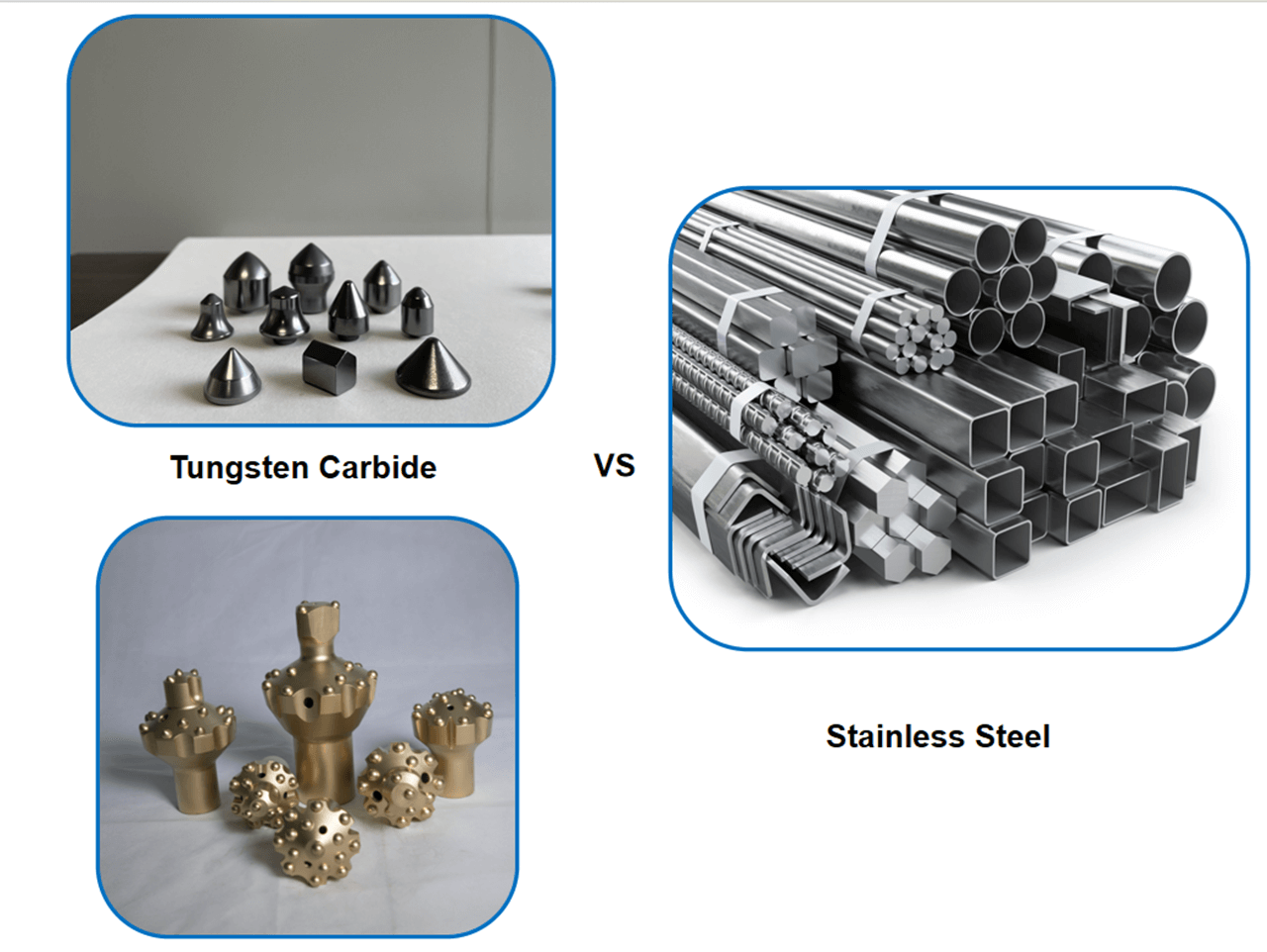

Tungsten Carbide And Stainless Steel: A Comparison Of Strengths And Suitability

Choosing between tungsten carbide and stainless steel for different applications is a common dilemma. Both materials offer unique properties and advantages. This article compares tungsten carbide and stainless steel and examines their strengths and suitability to help you make an informed decision.

Choosing between tungsten carbide and stainless steel for different applications is a common dilemma. Both materials offer unique properties and advantages. This article compares tungsten carbide and stainless steel and examines their strengths and suitability to help you make an informed decision.

Hardness and durability :

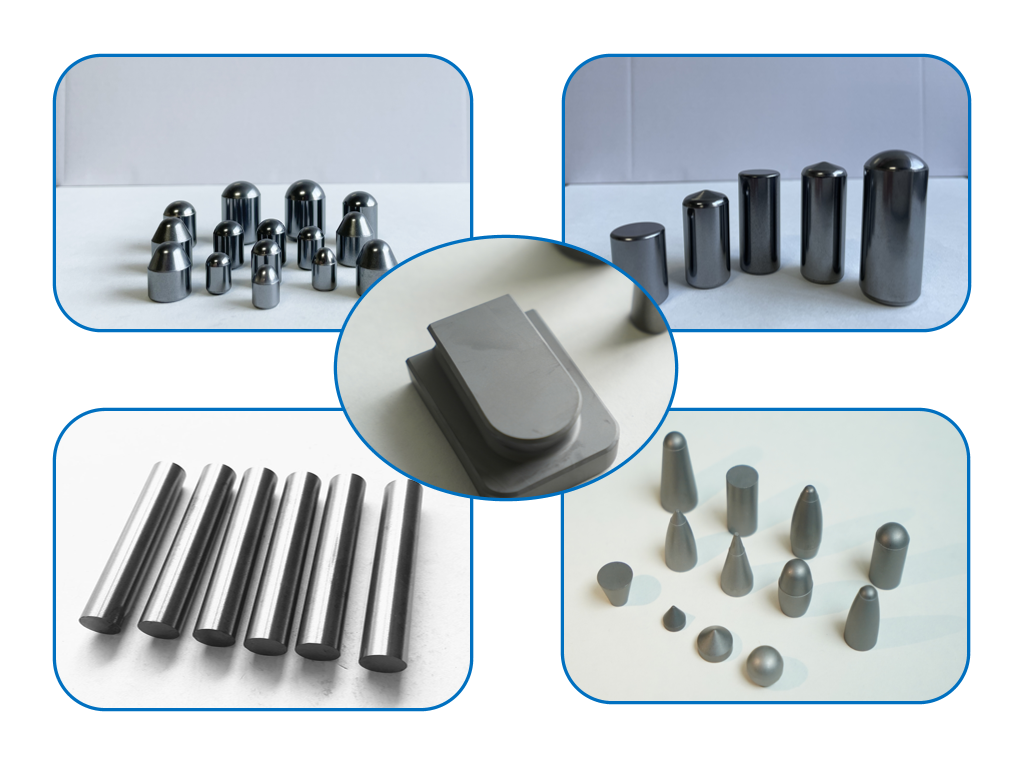

Tungsten carbide outperforms stainless steel in terms of hardness and durability. Its exceptional hardness and wear resistance make it ideal for demanding applications that require a long service life, such as cutting tools or industrial wear parts. Stainless steel, on the other hand, offers good corrosion resistance and is suitable for applications where rust and stain resistance is paramount, such as medical instruments or kitchen appliances.

Versatility and cost:

Compared to tungsten carbide, stainless steel is more versatile. It is available in different grades with different properties, allowing for a wide range of applications. Stainless steel is also less expensive, making it a good choice for applications that do not require extreme hardness or wear resistance. Tungsten carbide, on the other hand, is more expensive but offers superior hardness and durability, making it worth the investment in certain cases.

Conclusion:

The choice between tungsten carbide and stainless steel depends on the specific requirements of each application. Tungsten carbide is characterized by hardness and durability, while stainless steel offers corrosion resistance as well as versatility and cost-effectiveness.