The versatility and strength of tungsten carbide: an indispensable material

Tungsten carbide, a compound of tungsten and carbon atoms, is very popular in many industries due to its exceptional properties. This article examines the various reasons for the widespread use of tungsten carbide and its importance in numerous applications.

Tungsten carbide, a compound of tungsten and carbon atoms, is very popular in many industries due to its exceptional properties. This article examines the various reasons for the widespread use of tungsten carbide and its importance in numerous applications.

Unrivaled hardness and wear resistance :

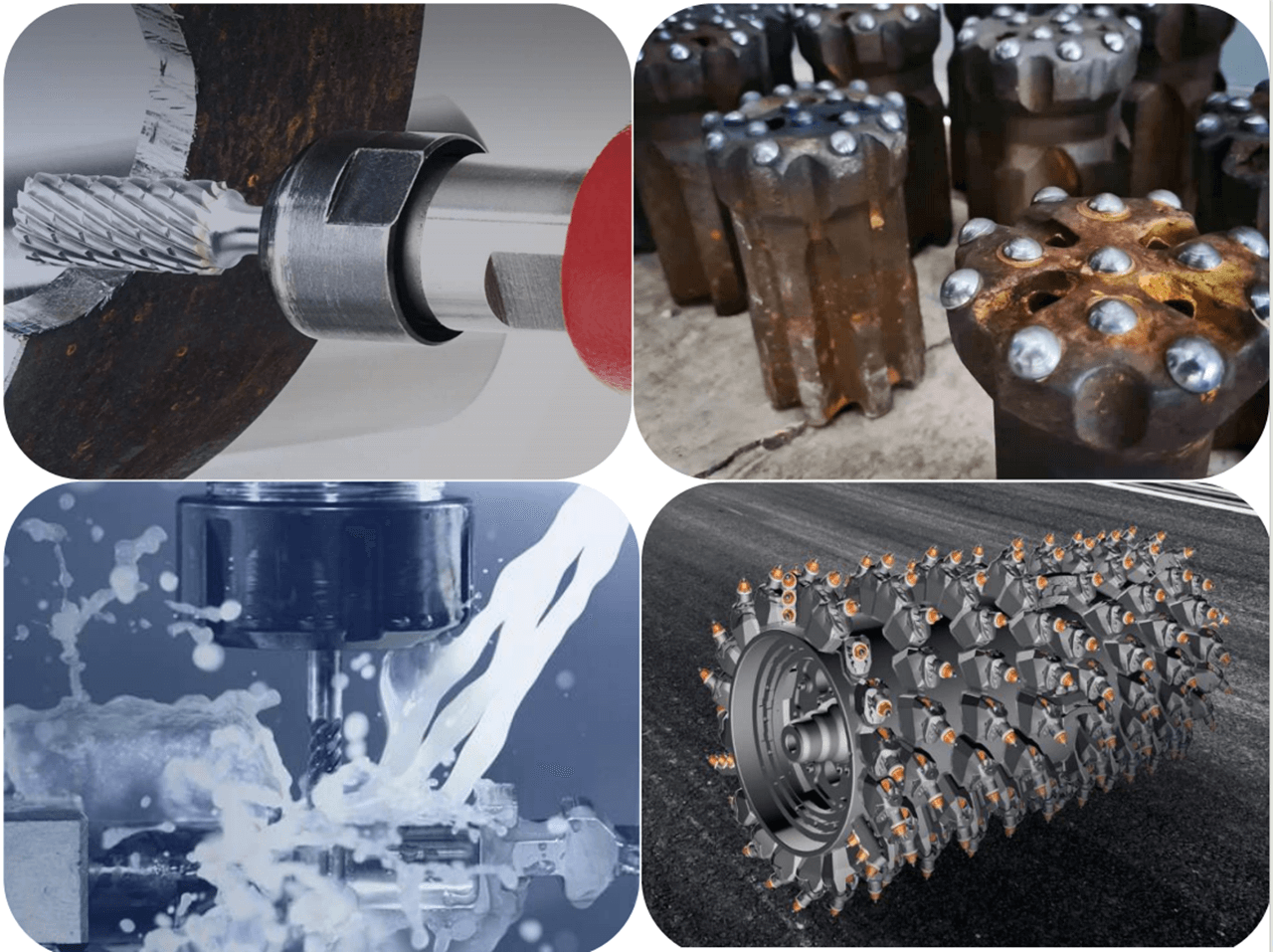

The remarkable hardness of tungsten carbide is one of its most sought-after properties. With a hardness comparable to diamond, it is exceptionally resistant to wear, abrasion and deformation. This makes it the preferred choice for cutting tools, drills, milling inserts and other industrial applications where durability and longevity are important. Tungsten carbide tools can withstand the rigors of high-speed machining, mining and metalworking, ensuring longer tool life and less downtime.

Superior strength and toughness :

In addition to its hardness, tungsten carbide exhibits exceptional strength and toughness. It can withstand heavy loads, extreme pressure and impact without deforming or failing. This makes it ideal for applications in industries such as oil and gas, construction and manufacturing. Tungsten carbide is used for wear parts, dies, punches and components in machinery and equipment to ensure that they function reliably even under difficult conditions.

Exceptional heat resistance:

Tungsten carbide’s ability to withstand high temperatures without losing its mechanical properties makes it invaluable in industries where heat resistance is critical. It is widely used in the aerospace, automotive and power generation industries. Turbine blades, nozzles and engine components made from tungsten carbide maintain their integrity and performance even at high temperatures, ensuring efficient operation and a long service life.

Chemical inertness and corrosion resistance:

Tungsten carbide has a high chemical inertness that makes it resistant to corrosion and chemical reactions. It remains stable when exposed to acids, alkalis and other aggressive substances. This property makes it suitable for use in the chemical processing, pharmaceutical and petrochemical industries. Tungsten carbide is used in valves, seals and other equipment that come into contact with corrosive substances and offers reliable and durable performance.

Versatility and customization:

Tungsten carbide offers great versatility and customization. It can be combined with different binders, such as cobalt or nickel, to create a range of grades and compositions. By adjusting the ratio between tungsten carbide and binder, manufacturers can tailor the properties of the material to specific applications. Thanks to this adaptability, tungsten carbide can be used in cutting tools, wear-resistant coatings, mining tools and even jewelry.

The exceptional hardness, strength, heat resistance, chemical inertness and versatility of tungsten carbide make it a highly sought-after material in various industries. Thanks to its excellent properties, it can withstand demanding conditions, extend tool life and improve overall performance. From industrial applications such as machining and mining to aerospace and defense, tungsten carbide continues to play an important role in advancing technology and pushing the boundaries of what is possible. Further research and development is expected to increase the importance of tungsten carbide, leading to further innovation and applications in the future.