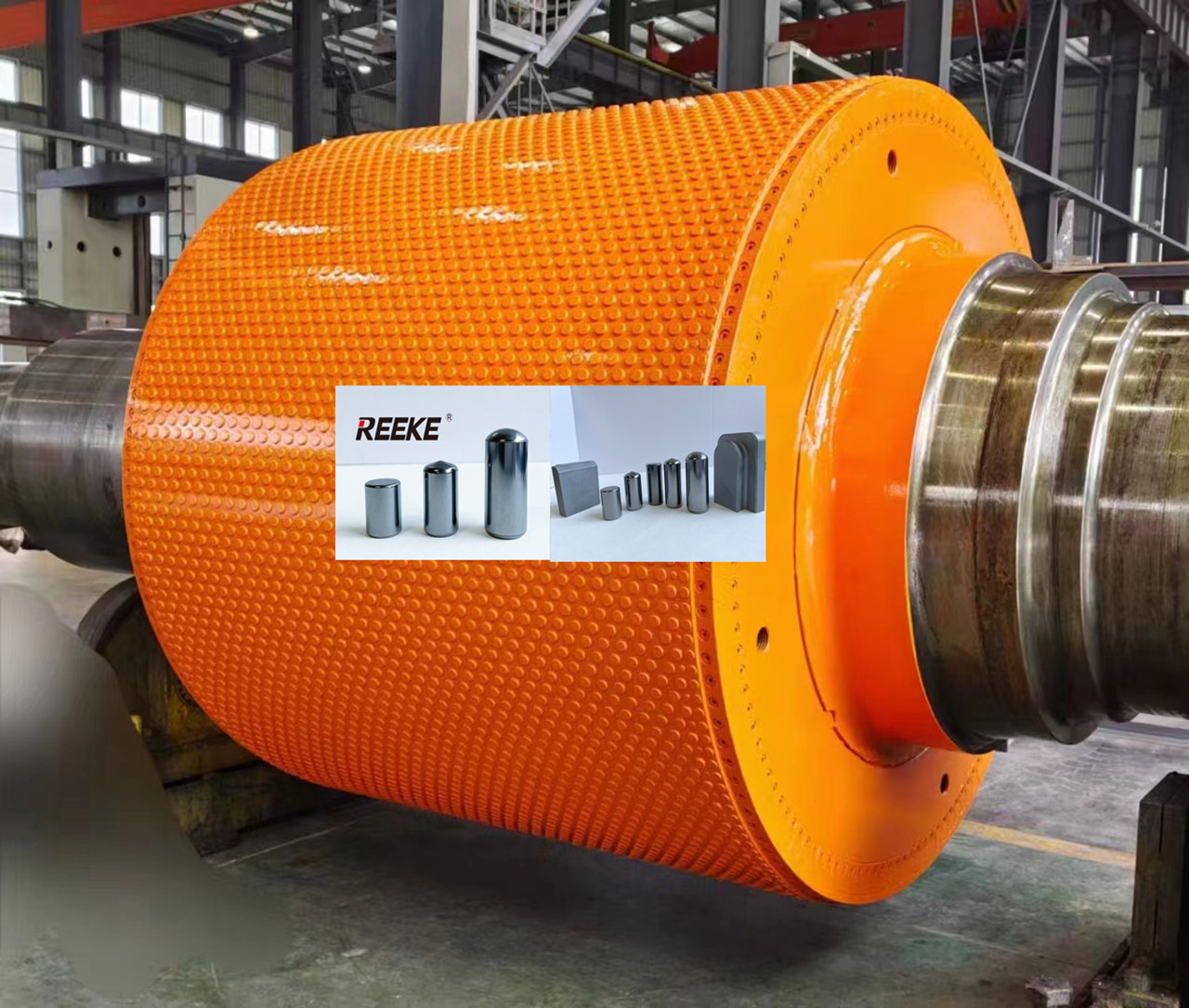

High Pressure Grinding Roller (HPGR)

HPGR is a solution to fine crushing of various types of mineral ores including iron, manganese, copper, gold, molybdenum, aluminum and diamond, and it is also functional to raise specific surface area in pelleting process significantly contrast with traditional methods.

HPGR is a solution to fine crushing of various types of mineral ores including iron, manganese, copper, gold, molybdenum, aluminum and diamond, and it is also functional to raise specific surface area in pelleting process significantly contrast with traditional methods.

HPGR will significantly improve the capacity of the crushing systems, as well as reduce electric energy and steel ball consumption of ball mill.

With features of high wear resistant roller surface, great crushing ratio, higher availability, investment and cost saving and flexible configuration, the HPGR is capable to process various kinds of ore 50-2000t/h.

It has various advantages including solid structure, wearable roller surface, high efficiency and energy-saving.

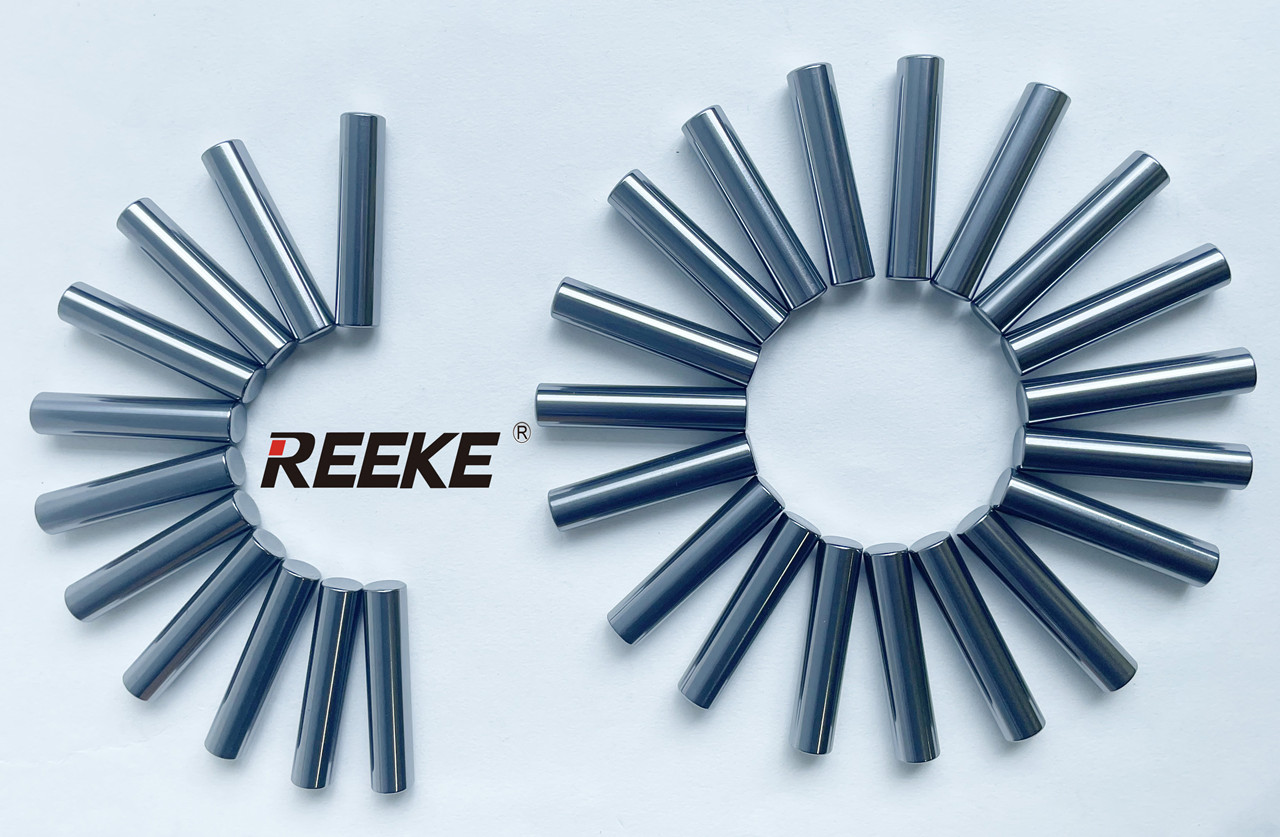

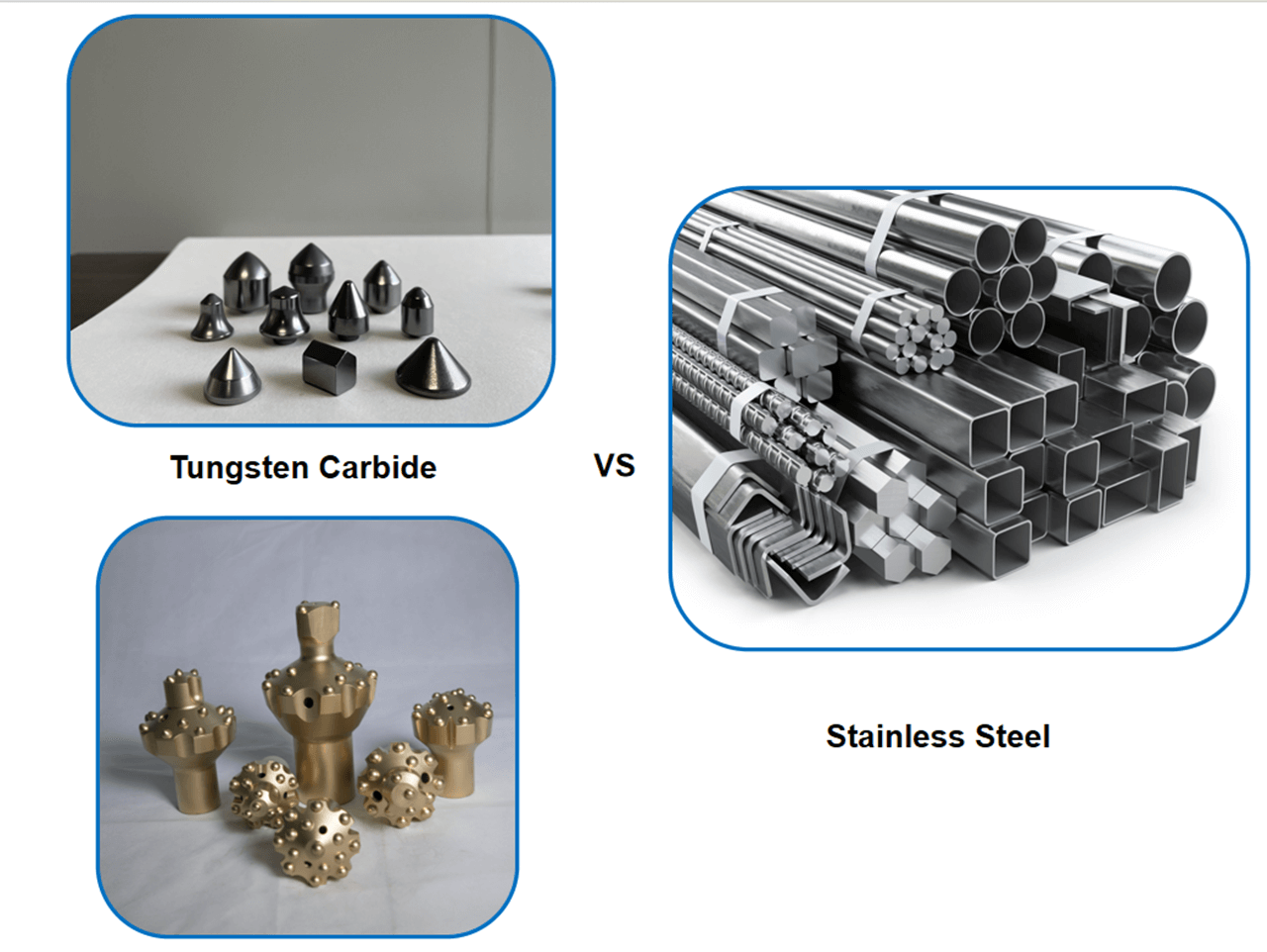

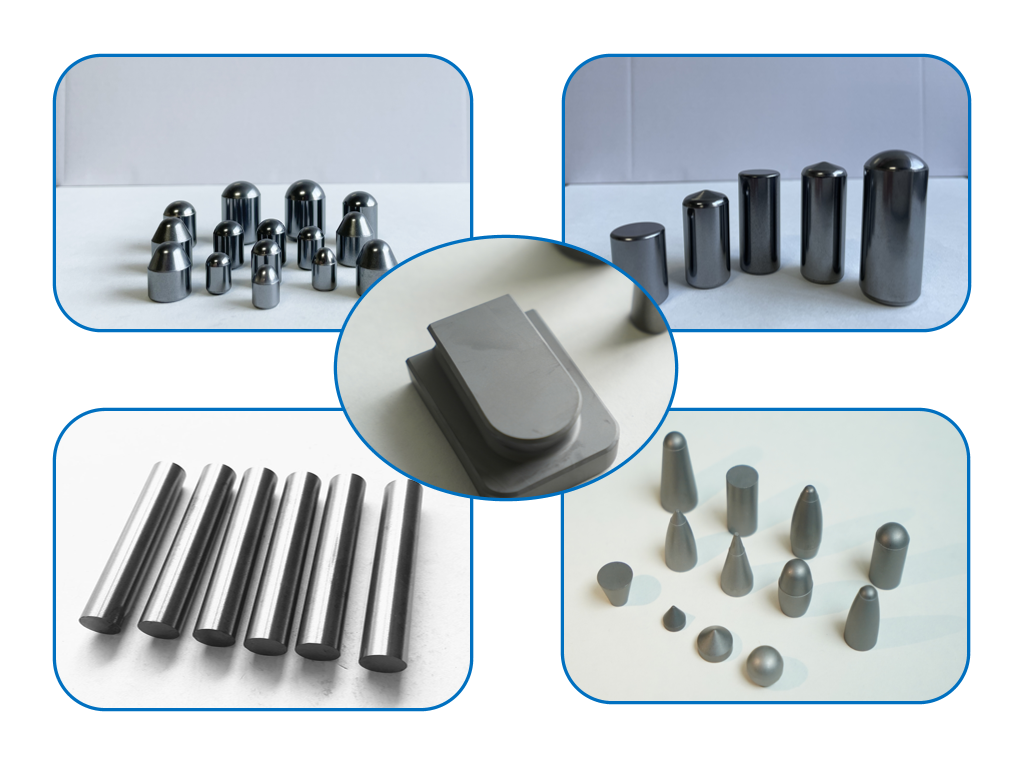

The process of forming a wear-resistant layer on the roller surface by inlaying carbide studs on the roller surface promotes the technological innovation of roller mills, and also makes the roller mills more adaptable, expands the application fields, and has a longer service life and higher efficiency.

Reeke Carbide Studs&Blocks of various sizes and grade, welcome your inquiry.