Exploring The Weaknesses Of Tungsten Carbide

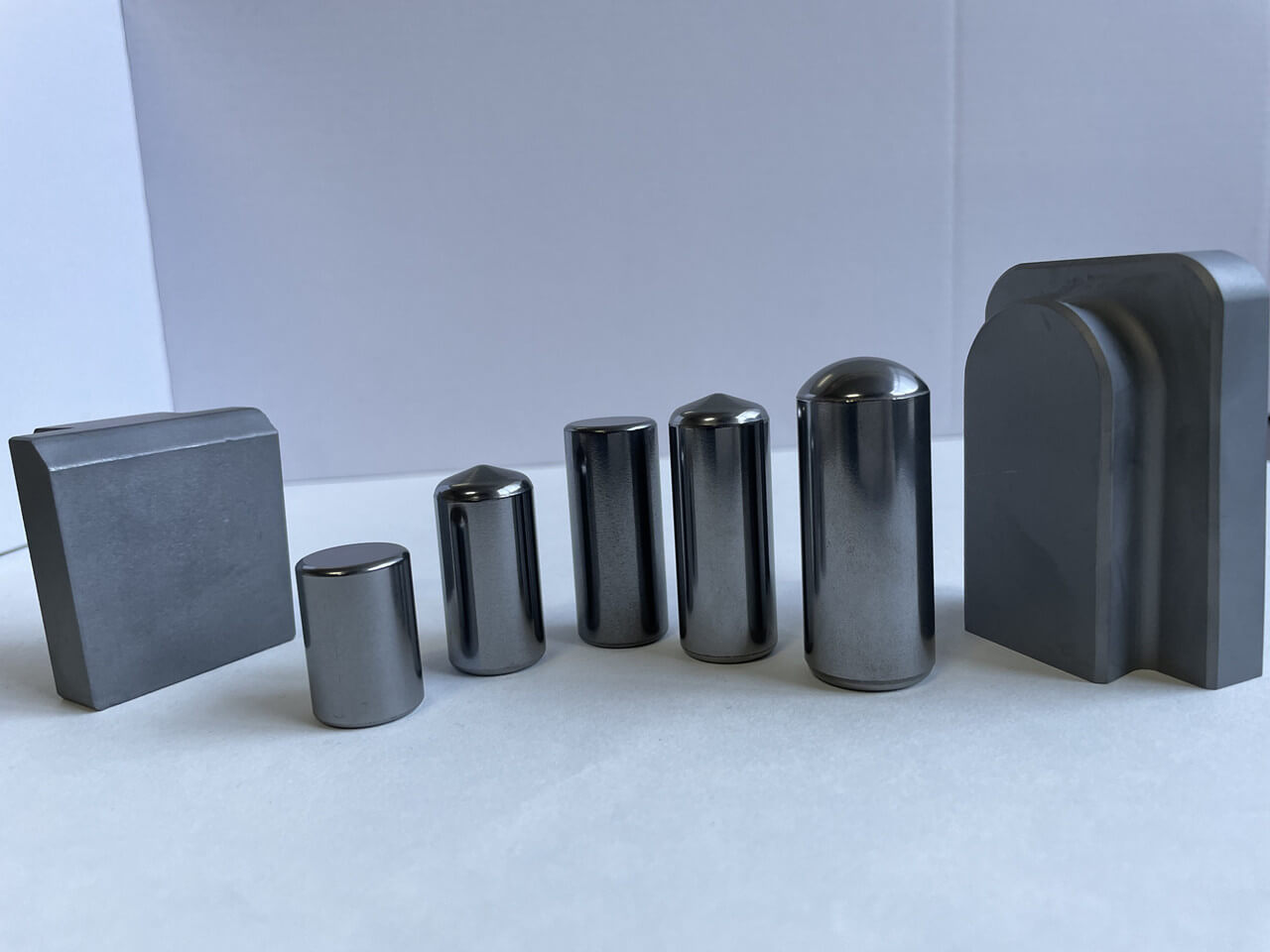

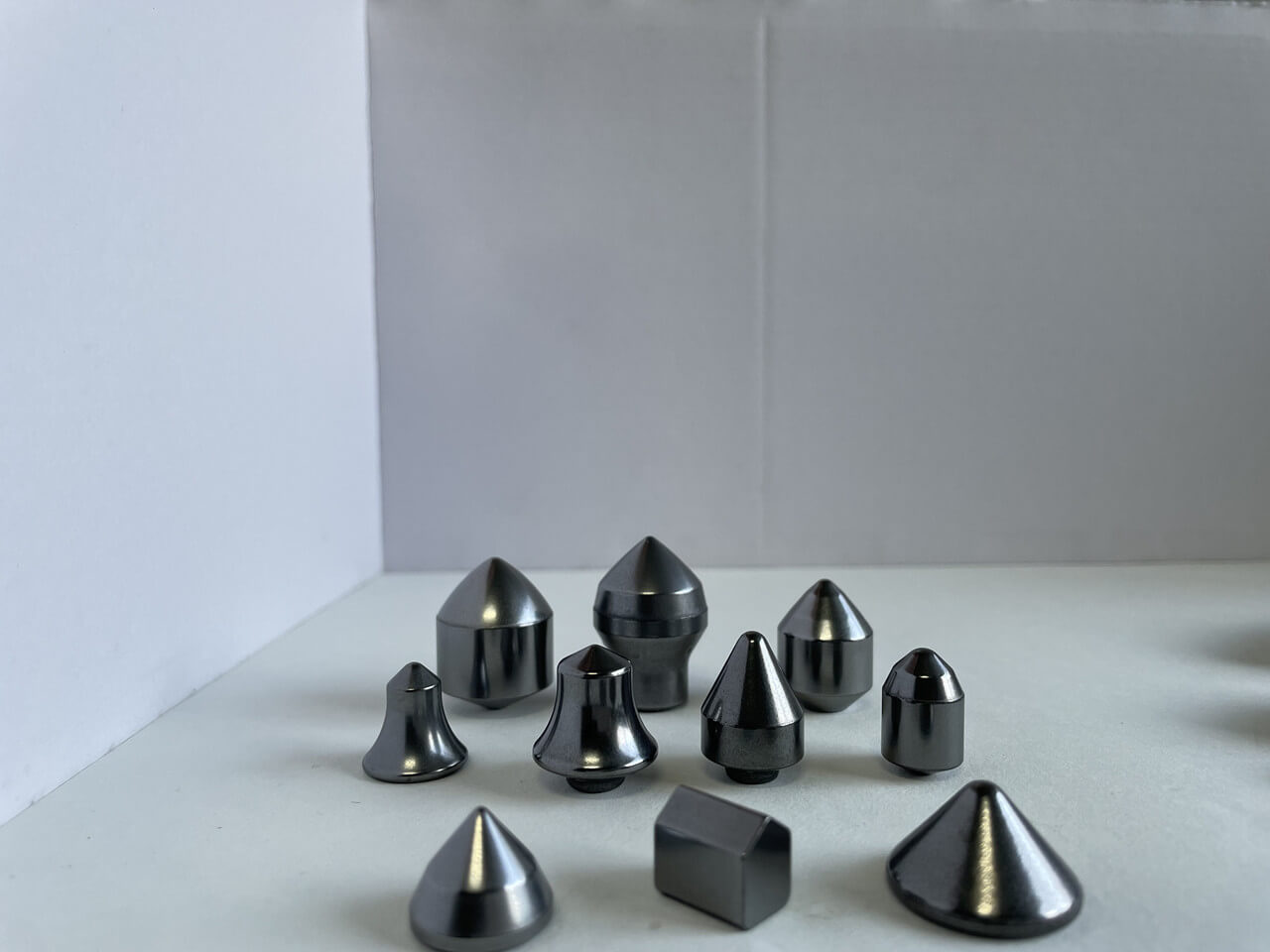

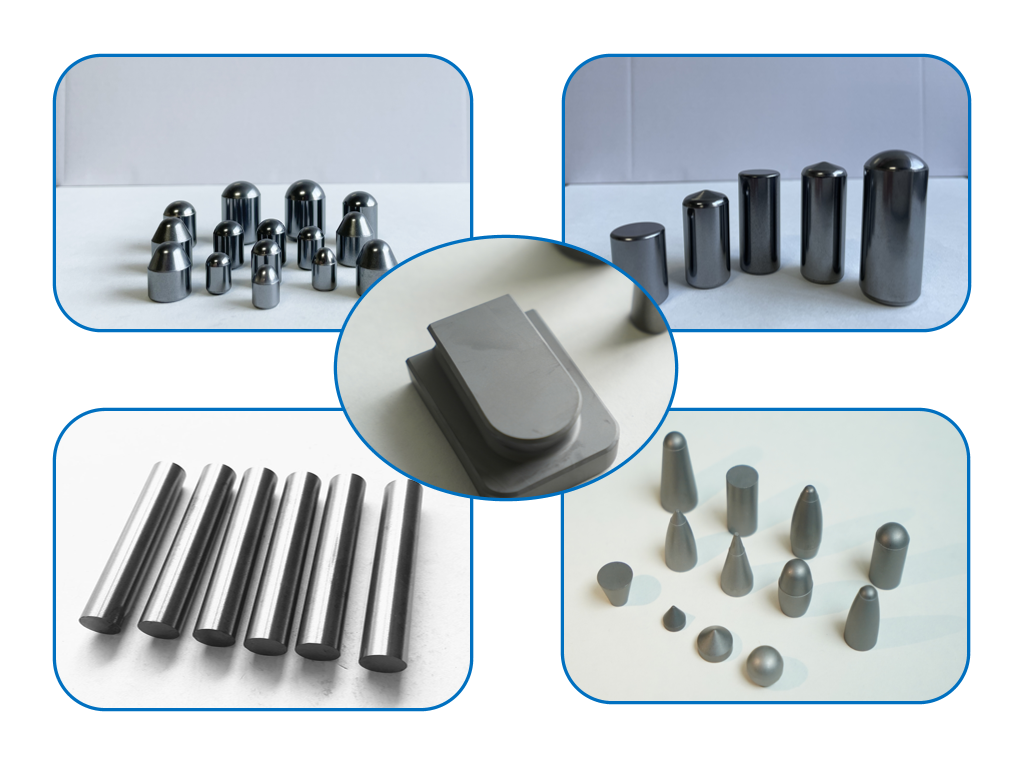

Tungsten carbide, known for its exceptional hardness and durability, is a highly sought-after material in various industries. However, this remarkable compound also has its weaknesses. This article looks at the weaknesses of tungsten carbide and highlights its limitations to provide a comprehensive understanding of its properties.

Introduction :

Tungsten carbide, known for its exceptional hardness and durability, is a highly sought-after material in various industries. However, this remarkable compound also has its weaknesses. This article looks at the weaknesses of tungsten carbide and highlights its limitations to provide a comprehensive understanding of its properties.

Brittleness :

One of the biggest weaknesses of tungsten carbide is its brittleness. Although it has exceptional hardness, tungsten carbide can break or chip under certain conditions. Due to its rigid and dense atomic structure, it can be prone to cracking under sudden impact or excessive stress. This brittleness limits its use in applications that require high ductility or resistance to deformation without fracture.

Susceptibility to corrosion:

Another weakness of tungsten carbide is its susceptibility to corrosion. Although tungsten carbide itself is highly resistant to corrosion, the presence of a binder metal, usually cobalt, can make it susceptible to chemical attack in corrosive environments. The binder can degrade over time and reduce the overall performance and integrity of the tungsten carbide. This limitation requires careful consideration of operating conditions and appropriate material selection for applications where corrosion resistance is critical.

Conclusion :

While tungsten carbide possesses exceptional hardness and durability, its weaknesses, such as brittleness and susceptibility to corrosion, should be taken into account when considering its use in various industries.